CMP

CMP Foundry service

CMP foundry services

Representative examples of CMP process

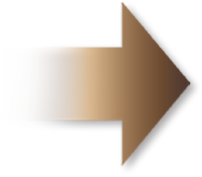

| Damascene (embedded) CMP |

CMP of polycrystalline | CMP before bonding |

| CMP for TSV | CMP to remove step height | CMP before hybrid bonding |

| CMP to adjust film thickness | CMP to improve surface roughness | CMP of difficult-to-cut material |

- ・CMP before bonding processes such as room temperature bonding, C2W, plasma-activated bonding

- ・CMP to expose metal electrode (gold rush process) / CMP of insulation layer

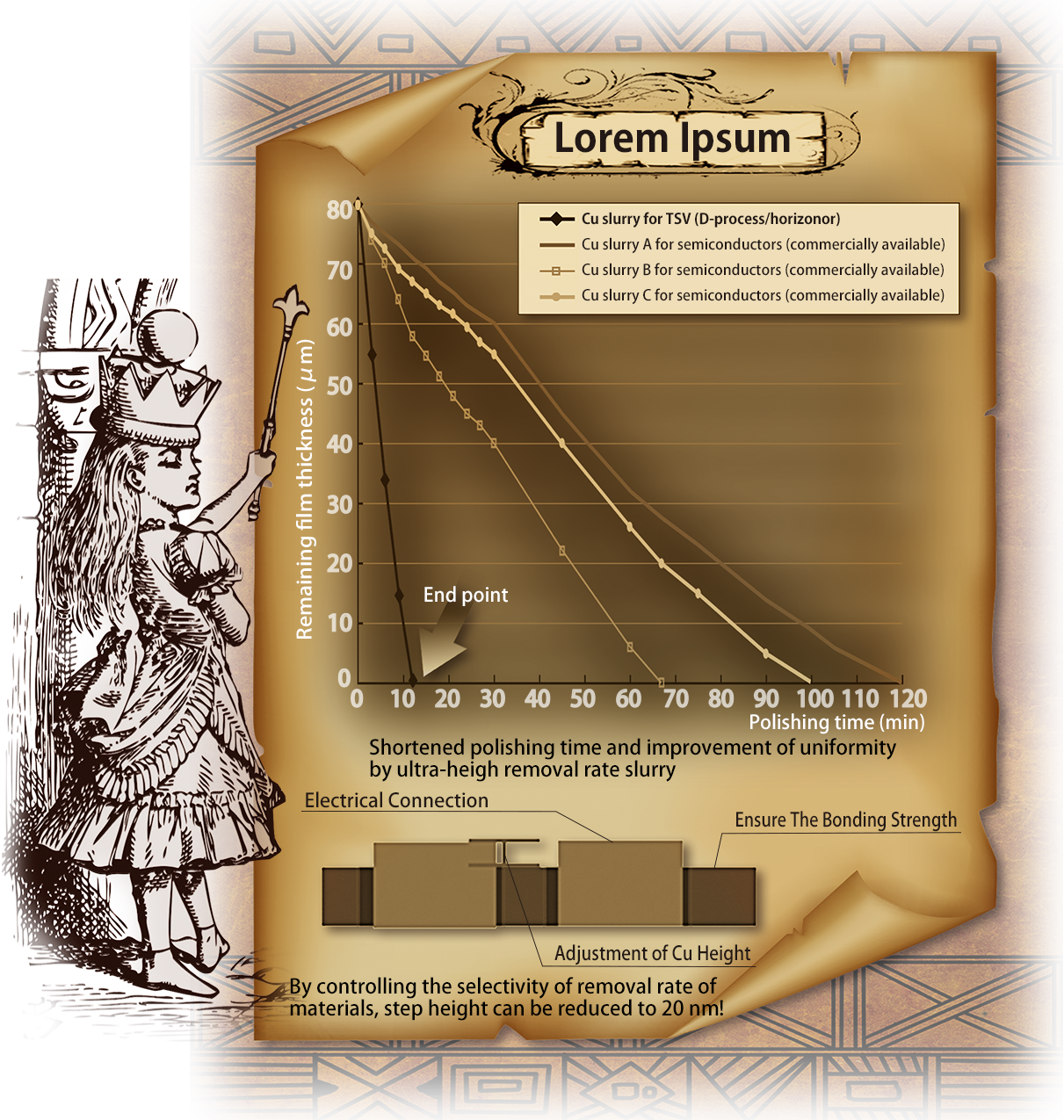

- ・Cu CMP with ultra-high removal rate

- ・CMP process for Si power devices

- ・CMP process for HDD (track media, patterned media)

- ・CMP of single crystal and polycrystalline difficult-to-cut materials (SiC, GaN, etc...)

- ・Other CMP foundry services

D-process is a front runner of CMP foundry

- We have expanded our business by our slurries and planarization technologies.

- Au surface roughness Ra < 0.2nm

- Cu ultra-high removal rate; over 10 μm/min

- Au removal rate; over 1 μm/min

- SiO2 surface roughness Ra < 0.1nm

- Polycrystalline material surface roughness Ra < 0.3nm

- Controlling of removal rate selectivity of various materials

D-process optimize our slurries for various device wafers!

Abrasives, etchants, inhibitors, oxidants, storage stabilizers, contact angle adjusters, thickeners, lubricants, agents for step height removal, pH buffers, etc.

Slurry/horizonor for CMP foundry services

D-process optimize abrasives and chemicals in slurry for various devices and materials

D-process optimize abrasives and chemicals in slurry for various devices and materials

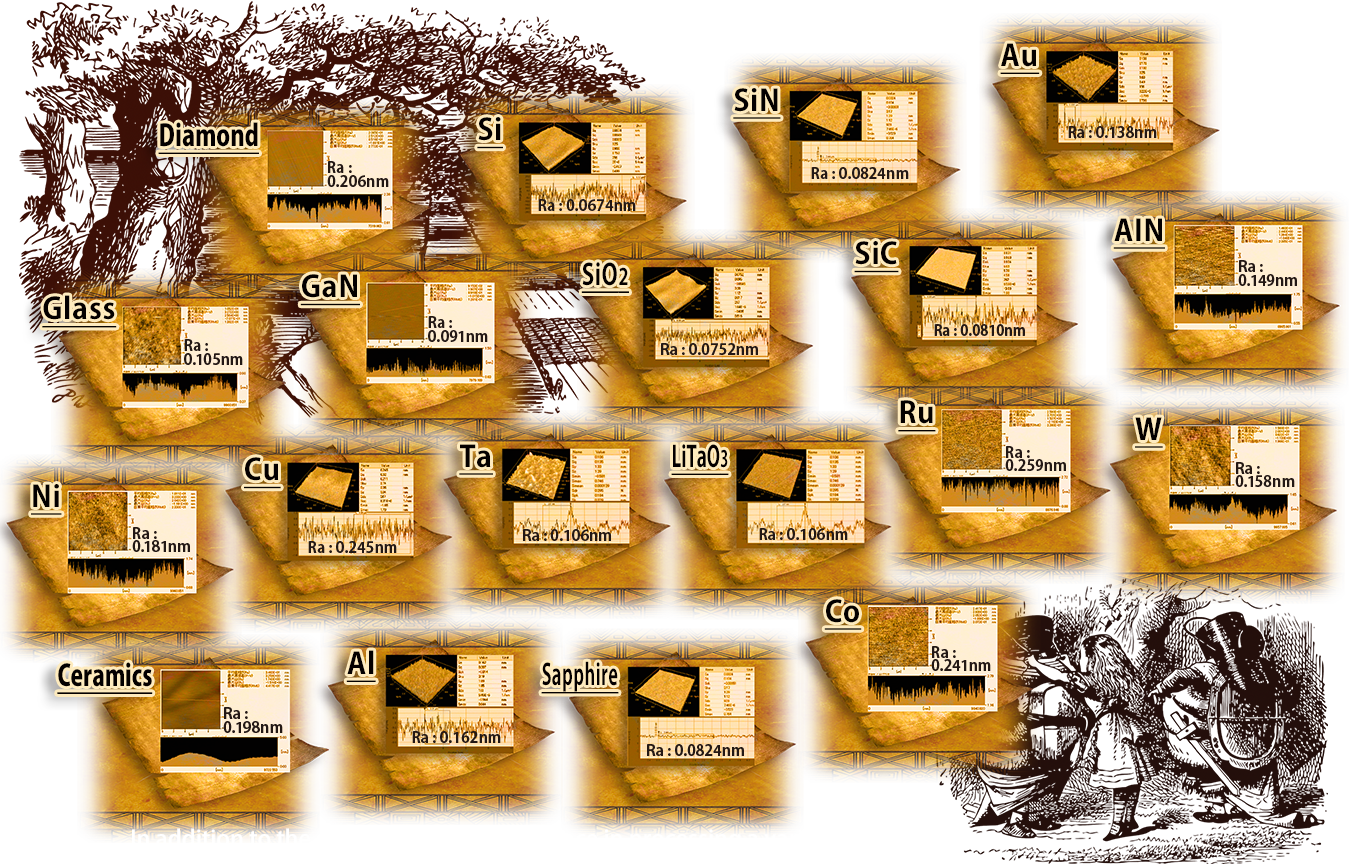

Achievement of super-smooth surface by CMP

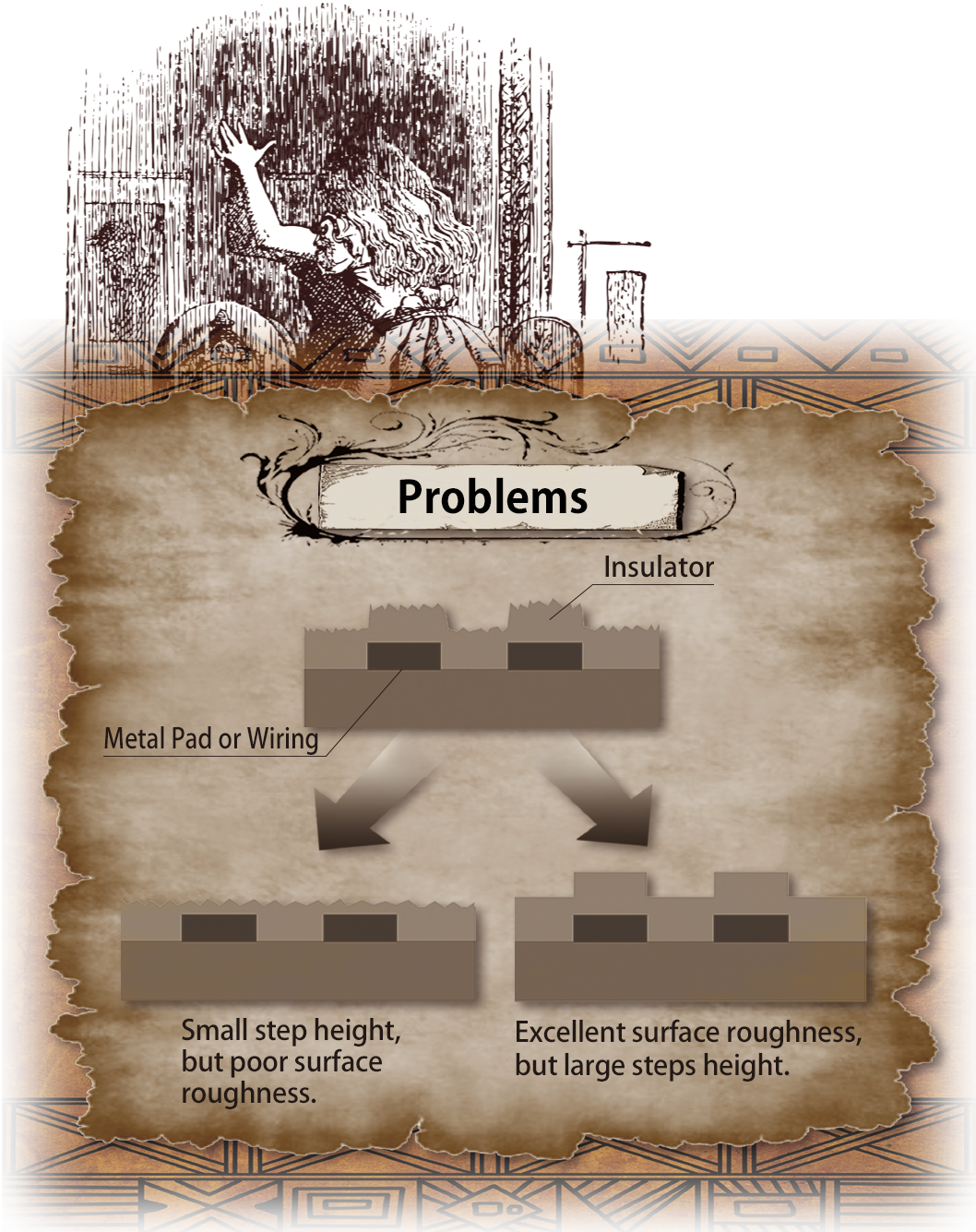

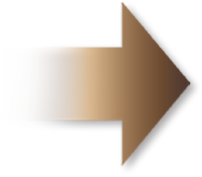

Step height reduction

CMP of difficult-to-cut materials & polycrystalline materials

Cu CMP process with ultra-high removal rate

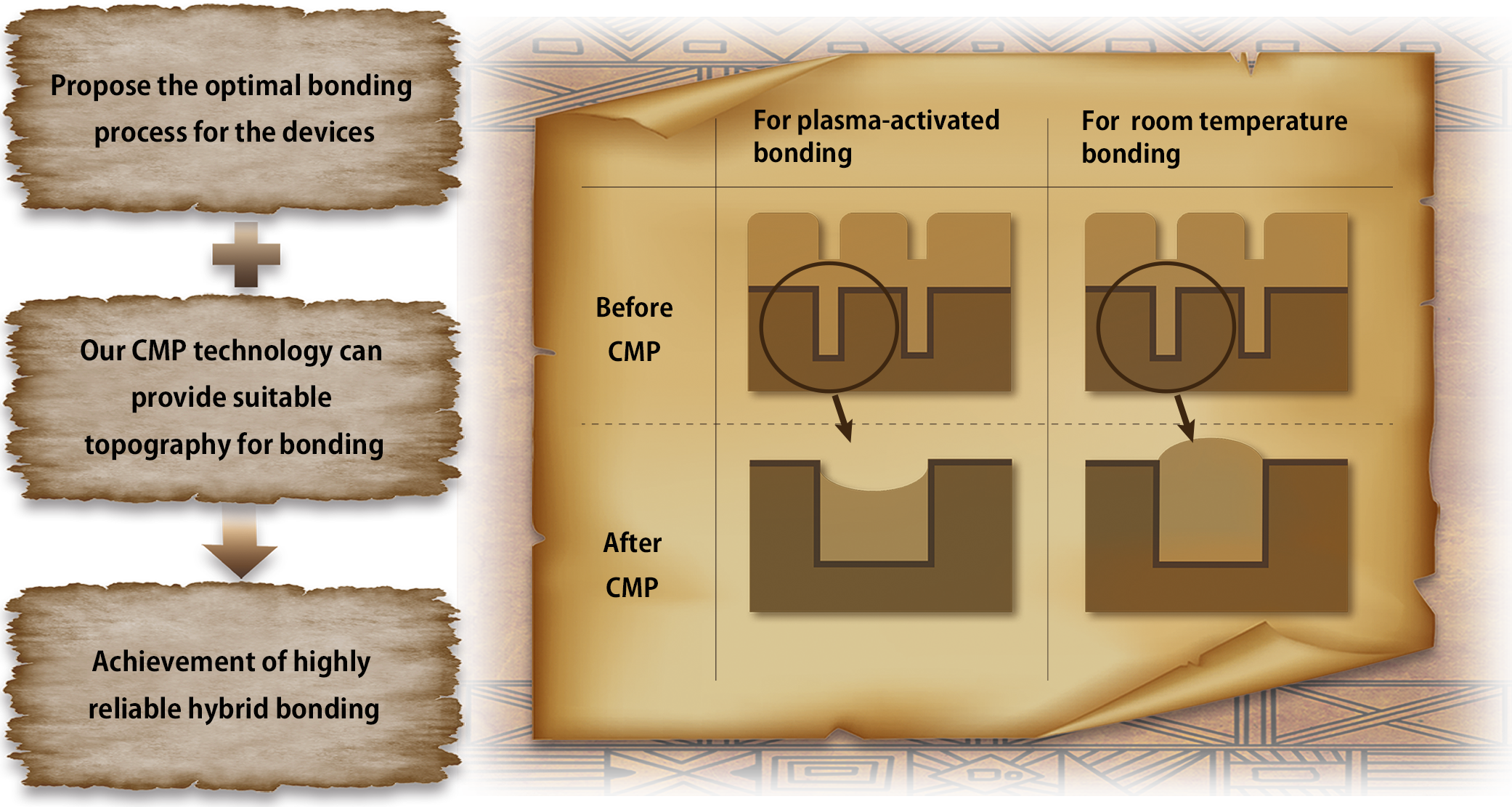

CMP process for Cu-SiO₂ hybrid bonding